Canada’s oil and gas industry takes seriously its responsibility to conduct fracking in a way that safeguards the quality and quantity of water.

Water is a key component of most hydraulic fracturing, or fracking, operations. During fracking, water is required to:

- Transmit pressure downhole to create cracks, or fractures, in the rock

- Carry proppant (usually sand) into the targeted rock to hold the fractures open

The industry understands that increased use of fracking has raised questions about the amount of water it requires and if fracking can contaminate local surface and groundwater.

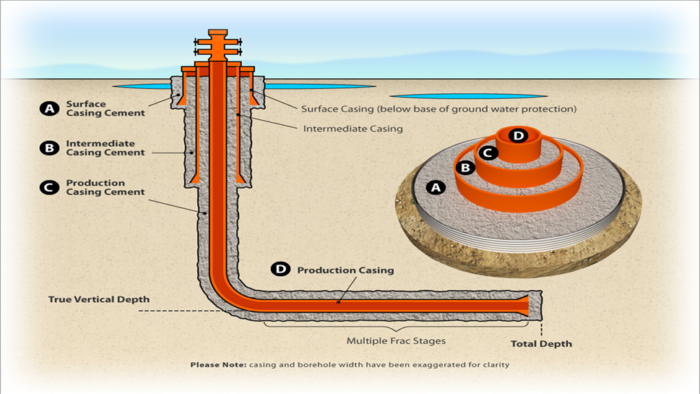

Scientific evidence indicates that water contamination from the frac zone has not occurred. This is partially due to the significant vertical separation between the target zone for fracking and freshwater aquifers. Fracking generally occurs between 1.5 and 4 kilometres below the surface. Drinking water aquifers are typically less than 300 metres below surface. In addition, wells are constructed with multiple layers of steel casing and cement to ensure the fluids that flow down and up cannot migrate outside of the well.

(The illustration below is not to scale. The distance between the surface casing and the horizontal well is much greater in reality.)

Source: Trican

Regulations and Industry-driven Measures to Protect Water

Continuing to safeguard the quality and quantity of regional surface and groundwater is a commitment the companies that own the well and fracking companies make to communities. In practical terms this means:

- Using sound wellbore construction practices,

- Sourcing alternatives to fresh water where appropriate, and recycling water for reuse as much as practical

- Developing technologies to reduce water consumption

- Measuring and disclosing water use

- Developing frac fluid additives with the least environmental risks

- Supporting the disclosure of frac fluid additives

- Developing a culture of environmental stewardship amongst workers

In addition, government regulations and practices require industry to undertake the following measures to ensure water is protected:

- Develop water and waste management plans and submit these for regulatory approval

- Track and report water allocation, use and disposition

- Ensure wellbore integrity through the life cycle of the well

- Real-time monitoring of data related to pumping of water during fracking operations

- Implementation of practices to avoid leaks and spills

- Outline equipment specifications and operational procedures for handling, transporting and storing flowback and produced fluids

- Practice and report proper fluid and waste disposal

Water Requirements for Fracking

Water volumes required for fracking vary greatly from region to region. Small volume fracs could be 500 to 2,500 m3 per well, moderate volume fracs might be 10,000 to 50,000 m3 per well, while high volume fracs could lie between 50,000 to 100,000m3 per well.

For comparison, a golf course will use ~20,000 m3 of water every 28 days. The same amount of water will grow nine acres of corn each year.

To learn more about the range of water volumes used in different regions, go to FracFocus and search wells in a specific area of interest.

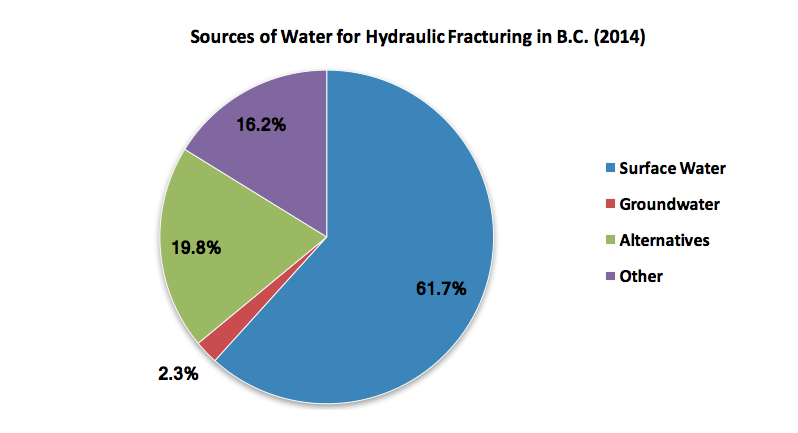

Water for a specific frac job might have several different sources, including: surface water bodies, groundwater, and industrial waters including recycled frac water. These sources are mixed at the wellsite. Regulators require permitting and tracking of water allocations and water used by operators.

Source: British Columbia Oil and Gas Commission

Since there are competing demands for fresh water, industry continues to develop technologies to reduce its usage in fracking, including:

- Sourcing deep saline aquifer water

- Sourcing industrial/community waste water

- Reusing and/or recycling flowback fluid

- Developing new additives that can be used with flowback and produced water

- Developing less water-intensive fluids

Water Sourcing Practices

In addition to the rules and regulations required by governments and regulators, the Canadian Association of Petroleum Producer’s (CAPP) has developed the following operating practices that protect water resources used during fracking activities:

- #3 – Baseline Groundwater Testing establishes baseline characteristics of local and regional groundwater for monitoring of groundwater over time

- #5 – Water Sourcing, Measurement and Reuse outlines requirements to evaluate available water sources, measure water use and reuse water as much as practical

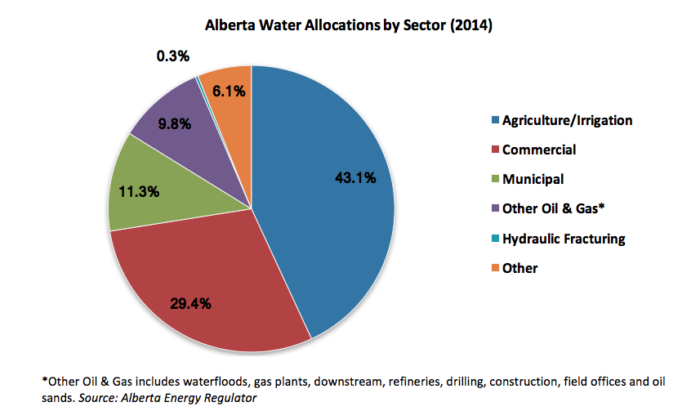

Water Permitting and Allocation

Government regulators monitor water use carefully. Water obtained for fracking must have appropriate approvals and permits. Regulators in each province allocate water for industry and other users.

The Northeast Water Tool (NEWT) is a tool that aids in water allocation in British Columbia. It provides guidance on water availability and is used to support decision-making for water-use approvals and licenses.

Flowback Fluid and Produced Fluid

A significant portion of the frac fluid that is pumped into the target rock to create cracks, flows back to the surface in the first weeks after fracking of the well is complete. This fluid is called “flowback” and the remainder of the flowback can flow to the surface over for up to several months. Flowback fluid is either recovered and held temporarily at the wellsite in containment tanks or, if a flowline is in place, it is recovered and stored at a central processing facility. Ongoing production from a fracked well may also continue to yield fluid. This is called produced fluid and it represents fluids that exist within the targeted rock formation.

Fluid Treatment and Re-use and Fluid Treatment

Industry continues to explore new methods of re-using flowback fluids to:

- Reduce wastewater volumes so that less is sent offsite for disposal

- Reduce the impact on local fresh water supplies

- Reduce truck traffic (less fresh water hauled) – lower impacts on roads, noise, and air quality

- Reduce use of energy

Fluid Disposal

A key element for safe handling and management of fluids related to fracking is permanent disposal of waste fluids. This part of oil and gas operations is closely regulated. For more information in British Columbia, see Disposal Wells: Produced Water summary sheet, and in Alberta, see Directive 051.

Regulations

The provinces have regulatory oversight of water sourcing, transportation, recycling, storage and disposal. Regulators in Alberta and British Columbia, place great importance on mitigating risks to surface water and non-saline groundwater sources.

Canadian Society for Unconventional Resources (CSUR) has compiles a report on the Canadian Water Regulations Applicable to Hydraulic Fracturing Operations.